Stand-Out Packaging & Displays

Brands that Trust Us

Stand-Out Packaging & Displays

Custom packaging solutions and expertise that get results

Brands that Trust Us

3,000+ brands big and small love us!

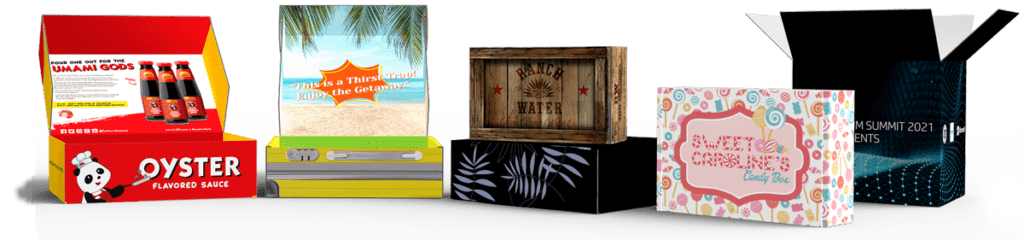

Customize your packaging and displays

Need a small quantity, fast?

Your Trusted Partner for Brand Packaging

Since 1983, Imperial Paper Co. has aided businesses in the development and production of custom packaging and promotional products.

- Innovative Packaging

- Creative Solutions

- Customer Satisfaction

- Offers Significant Value

- Continuous Improvement

- Conserving Natural Resources

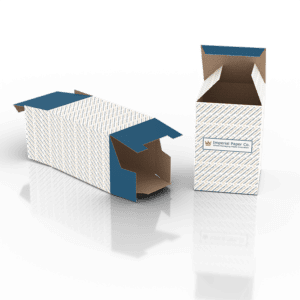

Package It Up Right

Presentation is Everything

Innovations In Packaging

Wow your customers with our custom design and custom packaging. We put our wide-ranging expertise to work and fully tailor packaging, boxes and displays to your needs.

Premium Packaging

Showcase what your brand represents with high-quality packaging.

Creative Packaging

Stand out in a crowd with innovative packaging

Environmentally Friendly

Trust eco-friendly packaging for less pollution during production

Unleash Your Brand's Potential with Our Packaging Solutions

Experience hassle-free packaging solutions that perfectly fit your business needs.

Your One-Stop Solution Shop for custom printed packaging

Get everything custom packaging that your business needs all in one place.

-

Rated 0 out of 5

-

Rated 0 out of 5

-

Rated 0 out of 5

-

Rated 0 out of 5

-

Rated 0 out of 5

-

Rated 0 out of 5

-

Rated 0 out of 5

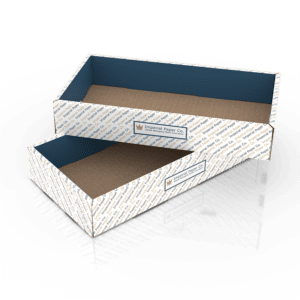

The Latest in Effective Packaging

The right packaging design makes a world of difference! Whether selling a product or ensuring an item is safely transported from one location to another, no one understands the importance of packaging more than we do! For decades, Imperial Paper Co. in Los Angeles, CA has been working with customers to design and manufacture specialty packaging products for retail boxes, POP store displays, corrugated inserts, packing and moving supplies, and much more. We are your go-to expert for unique, tailored packaging solutions.

Our cutting-edge design and fabrication technologies allow us to deliver products at highly competitive prices.

Known for our custom design and exceptional packaging manufacturing in the Greater Los Angeles area, we provide in-house design services, as well as flexo and litho printing—all backed by our tenured expertise in merchandising. Our talents and technologies deliver products that go above and beyond to get results. We want your products to succeed, and we’ll put all the weight of our business behind them to create an effective solution that works for you. Bring your concept or application to us today.

CREATIVE PACKAGING MADE SIMPLE

01

Design

Select your product and choose from existing designs or have our designers go to work.

02

Packaging In Process

Once your design is completed and approved, you will receive pricing.

03

Delivery

Place the order and we will deliver it to your warehouse. Thats it!

Los Angeles, CA and the surrounding areas

- North Hollywood, CA

- Toluca Lake, CA

- Studio City, CA

- Valley Village, CA

- Burbank, CA

- Universal City, CA

- Sun Valley, CA

- Van Nuys, CA

- Sherman Oaks, CA

- Glendale, CA

- North Hills, CA

- West Hollywood, CA

- Beverly Hills, CA

- Panorama City, CA

- Pacoima, CA

- Los Angeles County, CA

- Southern California